Factory supply proper price popular product pvc pe ppr pipe injection molding machine

Product Description

Products Description

Plastic injection molding machines are preferred for manufacturing medical products, as these machines offer high precision, accurate, and complex injection molded parts. Hydraulic Injection molding machine is the most popular machine type, primarily because of its long service life and a wide range of applications.The hydraulic injection molding machine consists of a fixed-speed, three-phase motor, and a variable-volume pump. Hydraulic injection molding machines have a long life, far drive distance, and low maintenance cost.This type of machine helps in significant reduction of production cycle time. Customers mainly use high-tonnage hydraulic machines for molding large parts. This machine is mainly used for producing high precision plastic components such as automotive parts, caps & closers, consumer goods, electrical & electronics goods, and medical items. Plastic injection molding machines are predominantly used in manufacturing automotive components, interior wrapping, and assembly parts, such as automotive exteriors, car lenses, interior components, under-the-hood components, and filter components.A strong shift in the use of plastics instead of iron and steel in the automotive industry is expected to drive the plastic injection molding machine market during the forecast period. Stringent government regulations have forced automotive manufacturers to use plastics instead of other materials such as iron and steel.Rapid economic growth, improved infrastructure, and rising middle-class population in emerging economies have led to an increase in vehicle production and sales, which, in turn, increase the demand for plastic injection molding machines.

Screw Diameter(mm) | 58 |

Theoretical Shot weight (cm³) | 858 |

Shot weight (g) | 772 |

Clamping force (kn) | 3400 |

Toggle stroke (mm) | 580 |

Ejector stroke (mm) | 160 |

Space between tie bars (mm) | 640*640 |

Mould thickness (mm) | 270-650 |

Machine size (m) | 6.7*2.0*1.9 |

Machine weight (ton) | 10.8 |

More Products

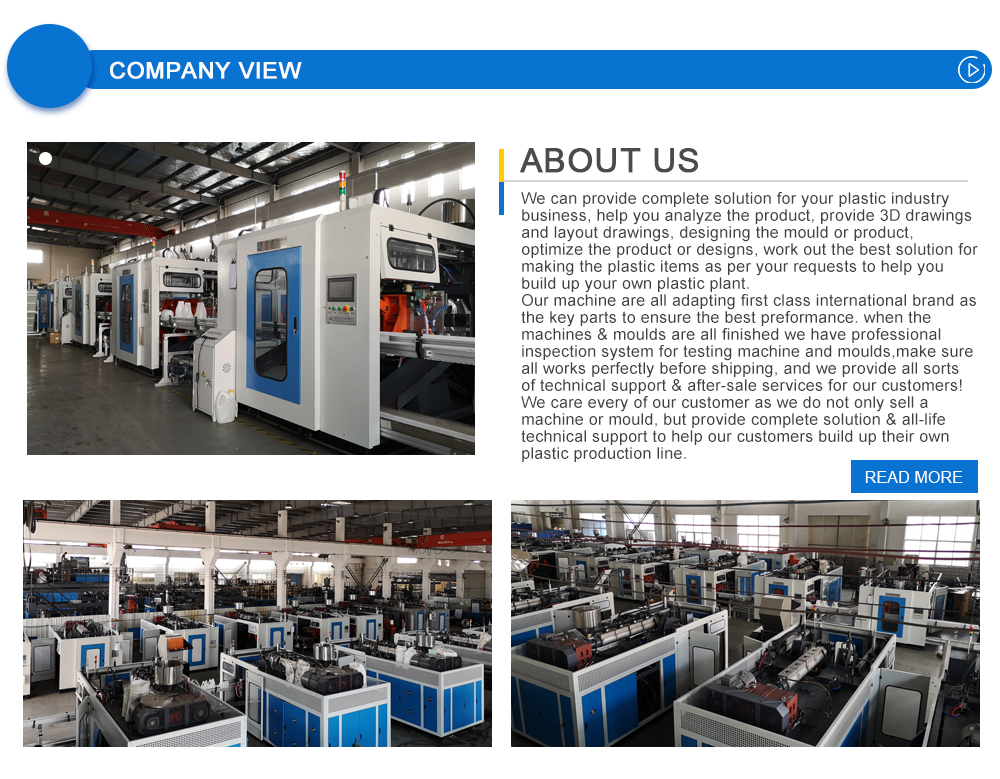

Company View

Production Line" class="magic-0">Production Line

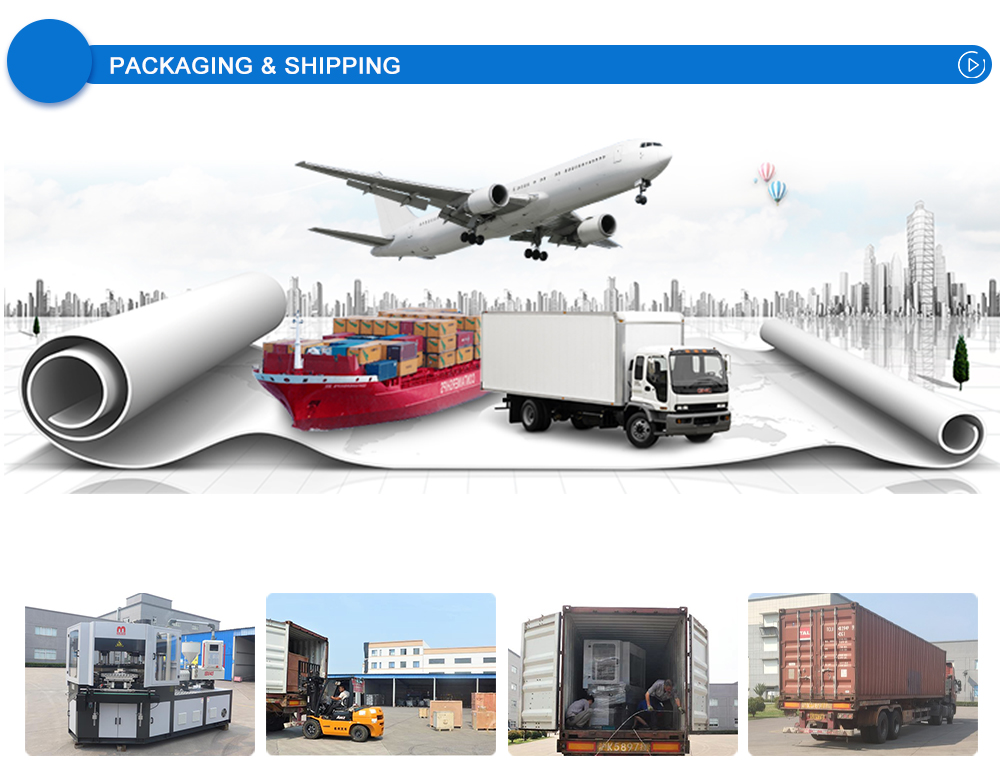

Packaging & Shipping

FAQ

Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support .

Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support!and bottles in all shapes.

Product Categories : Injection molding machine

Premium Related Products

Other Products

Hot Products

200t hand injection moulding machine/bottle injection molding machineinjection plastic mould,plastic mould,preform mould28mmplastic injection mold /plastic preform moldAutomatic filling machine 5 gallon bottle PETReverse osmosis systembottle design48 cavity bottle cap mouldTwo cavity semi automatic blowing machineFully-automatic blow moulding machine(6 cavity)Factory surpplying438tons pvc pipe fitting injection moulding machineplastic injection moulding machine priceinjection molding machine price HDX2000 IIPET BOTTLE PREFORM INJECTION MOLDING MACHINE HDX208PET FOR SMALL VOLUMEready made high quality pet preform mouldHDJS128 high quality hot sale disposable syringe making machineshaver injection molding machine