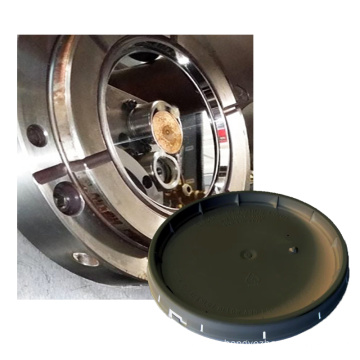

200L 210L 220L 240L 250L Open Top Drum Oil Drum Barrel Plastic Screw Cover Lid Cap Injection Mold

Product Description

Advantages

Dawson engineer team has more than 16 years of experience in blow molding industry. Our blow molding products include scraping

lubricating oil bottles, daily chemical products bottles, cosmetics bottles, chemical barrels, auto parts, etc; There is not only

a professional team, but also a highly configured production workshop to provide customers with the highest quality blow molding

molds and complete Plastic Products solutions, including blow molding machines, Auxiliary machines and automatic packaging lines.

lubricating oil bottles, daily chemical products bottles, cosmetics bottles, chemical barrels, auto parts, etc; There is not only

a professional team, but also a highly configured production workshop to provide customers with the highest quality blow molding

molds and complete Plastic Products solutions, including blow molding machines, Auxiliary machines and automatic packaging lines.

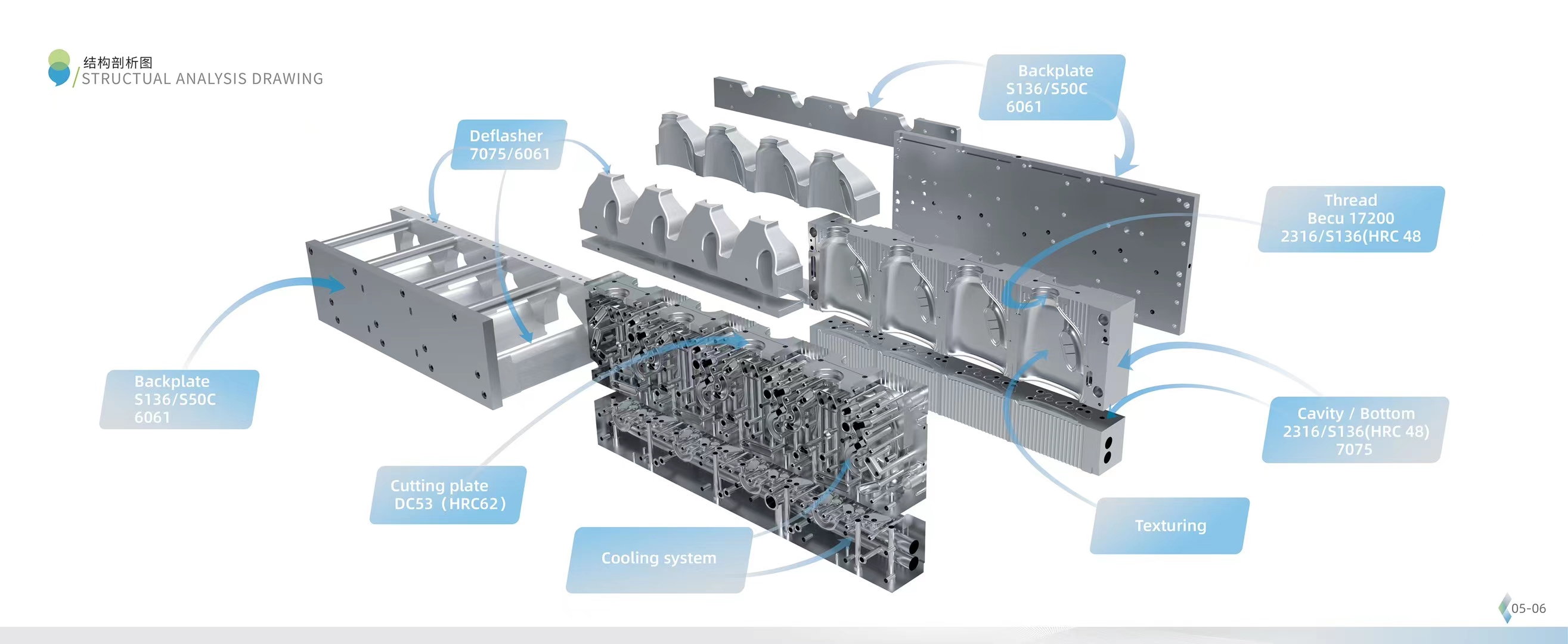

1. Mould cavity & Cutting edges use high quality Stainless steel S136H, which is the best material for blowing Moulds . | ||||||||

2. Our necking plate is using imported JAPAN material DC53,Heat treatment to HRC62. | ||||||||

3. Our cooling system is covered very average,all the necking area, handle area had designed perfect cooling system to make sure long time smooth running. | ||||||||

4. Our de-flashing unit and mask material is using High quality Aluminium alloy 6061#. | ||||||||

5. De-flashing cylinder all use high quality Taiwan AIRTAC cylinder. | ||||||||

Products Description

DAWSON MACHINERY & MOULD GROUP

High Grade Blowing Molding Mould

In the blow molding process, blow molding mold is an essential and important part. A good blow molding mold makes the molding more

smooth, the finished product more beautiful and smooth, and reduces the influence of burr on the appearance and use of the

product.

About mould material:

* Steel S50C#: Basic material for blowing moulds, competitive price

* Steel P20#: Common blow molding mould material, medium quality

* 2316 stainless steel: High quality mould material stainless steel.

* S136H : High quality blow molding steel, very durable and strong.

* Aluminium 7075# inserted beryllium copper: the best blow molding mould material,

aluminium mould has good cooling, and beryllium copper is very durable as well.

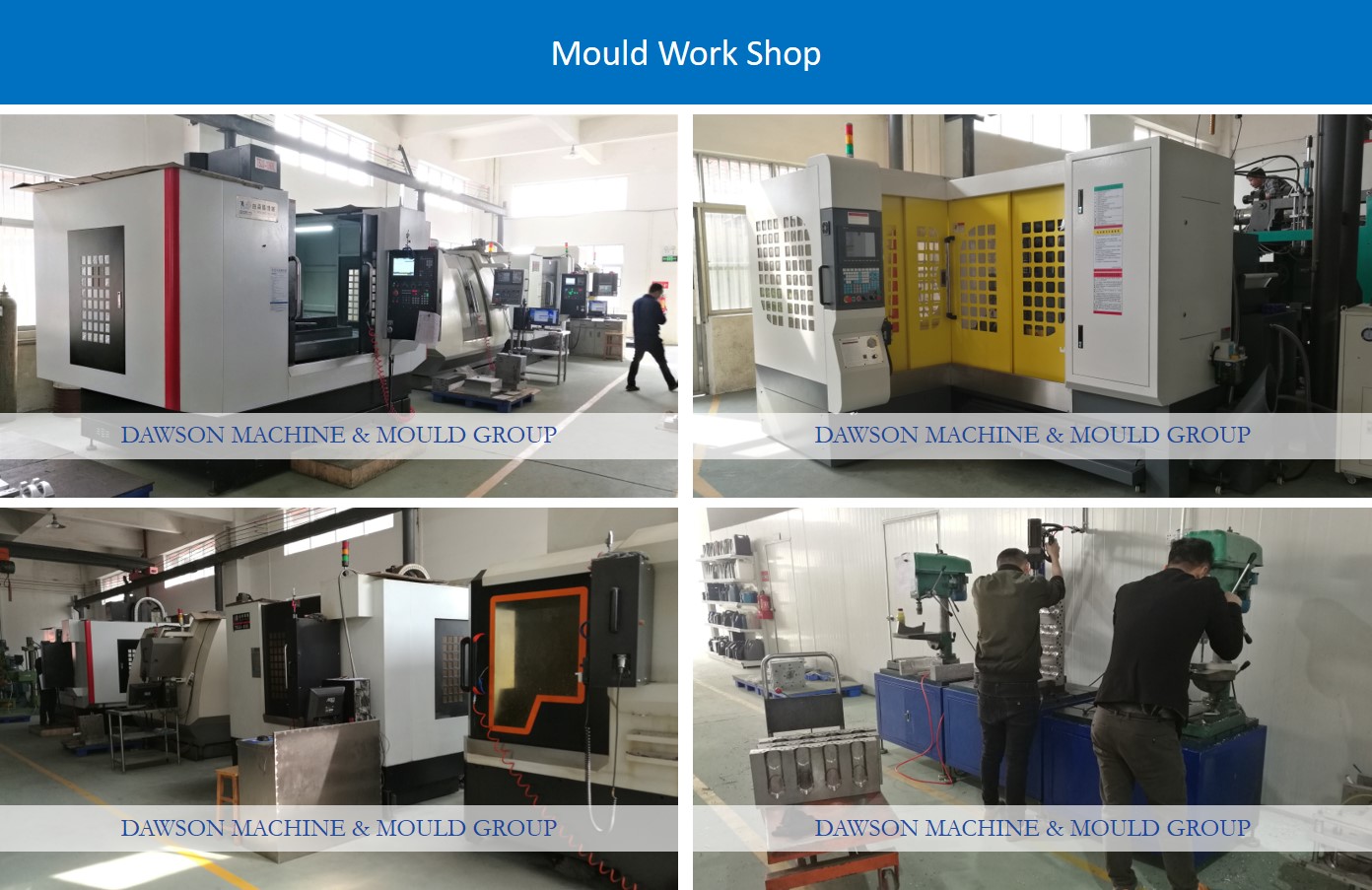

Professional Workshop

Our professional blow molding machine workshop...

High Quality Mould

In the process of plastic blow molding, the mold is a very important part. A good blow mould can make the product production more smoothly, and a good blowing mold can also make the finished product more flexible and beautiful.

We have our own mold production workshop, using high configuration equipment and mold engineers with 16 years of technical experience to customize blow molding mold for you.

- We use the best stainless steel S136H or Aluminium alloy 7075# as mould main material- Necking plate use JAPAN DC53 Heat

treatment to HRC62

- Double neck design available to change in future as a spare part necking

- All mould can be made auto-deflashing or manual deflashing as per customer requests

- Perfect mould cooling design to ensure the best moulding preformace

- Available to provide 2D & 3D product drawing for customers

- Available to send samples to customer for approval the product quality

- We had already made moulds for TOTAL,SHELL,GULF,BMW,YAMAHA,MOBIL,TOYOTA,MENGNIU, HYUNDAI,MENTHOLATUM,UNILEVER,LEE KUM KEE...

In the process of plastic blow molding, the mold is a very important part. A good blow mould can make the product production more smoothly, and a good blowing mold can also make the finished product more flexible and beautiful.

We have our own mold production workshop, using high configuration equipment and mold engineers with 16 years of technical experience to customize blow molding mold for you.

- We use the best stainless steel S136H or Aluminium alloy 7075# as mould main material- Necking plate use JAPAN DC53 Heat

treatment to HRC62

- Double neck design available to change in future as a spare part necking

- All mould can be made auto-deflashing or manual deflashing as per customer requests

- Perfect mould cooling design to ensure the best moulding preformace

- Available to provide 2D & 3D product drawing for customers

- Available to send samples to customer for approval the product quality

- We had already made moulds for TOTAL,SHELL,GULF,BMW,YAMAHA,MOBIL,TOYOTA,MENGNIU, HYUNDAI,MENTHOLATUM,UNILEVER,LEE KUM KEE...

Applications

Some of our partners

Company Profile

DAWSON MACHINERY & MOULD GROUP

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

We have our own service team in

Saudi Arabia, Colombia, Panama, South Africa ...

DAWSON MACHINE & MOULD GROUP

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery,

blow molding machine, Injection molding machine, PET blow molding machine, injection blow molding machine, during the past 18 years, we always force our energy into new areas of plastic machinery, plastic packaging machinery, to update the technology, to learn advanced experience,

to confirm new theory and new design, we are forming a unique competitive advantage of our owns.

The machines from our company carry good quality and effective after-sales service, upon the market,

customers from more than 45 countries, we provide complete solution for your plastic industry

business, as well as all sorts of technical support & after-sale services!

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

Product Categories : Mould & spare parts

Premium Related Products

Other Products

Hot Products

200t hand injection moulding machine/bottle injection molding machineinjection plastic mould,plastic mould,preform mould28mmplastic injection mold /plastic preform moldAutomatic filling machine 5 gallon bottle PETReverse osmosis systembottle design48 cavity bottle cap mouldTwo cavity semi automatic blowing machineFully-automatic blow moulding machine(6 cavity)Factory surpplying438tons pvc pipe fitting injection moulding machineplastic injection moulding machine priceinjection molding machine price HDX2000 IIPET BOTTLE PREFORM INJECTION MOLDING MACHINE HDX208PET FOR SMALL VOLUMEready made high quality pet preform mouldHDJS128 high quality hot sale disposable syringe making machineshaver injection molding machine