Basic Info

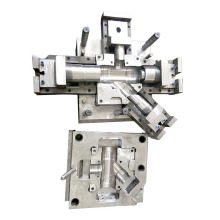

Model No.: YM-SLMJ

Click on the follow link to find out more information: https://www.ymaxmachine.com/plastic-injection-mold/

Company Info

- Company Name: Foshan Youngmax Machine Co.LTD

- Representative: David

- Product/Service: Hydraulic Press Machine , Punching Machine , Polishing Machine , Brazing Machine , Riveting Machine , Powder Painting Line

- Capital (Million US $): 1,000,000RMB

- Year Established: 2019

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 61% - 70%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 4

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: foshan guagndong

- Contact Person: Ms. Rachel

- Tel: 86-0757-81230839

Premium Related Products

Other Products

Hot Products

200t hand injection moulding machine/bottle injection molding machineinjection plastic mould,plastic mould,preform mould28mmplastic injection mold /plastic preform moldAutomatic filling machine 5 gallon bottle PETReverse osmosis systembottle design48 cavity bottle cap mouldTwo cavity semi automatic blowing machineFully-automatic blow moulding machine(6 cavity)Factory surpplying438tons pvc pipe fitting injection moulding machineplastic injection moulding machine priceinjection molding machine price HDX2000 IIPET BOTTLE PREFORM INJECTION MOLDING MACHINE HDX208PET FOR SMALL VOLUMEready made high quality pet preform mouldHDJS128 high quality hot sale disposable syringe making machineshaver injection molding machine