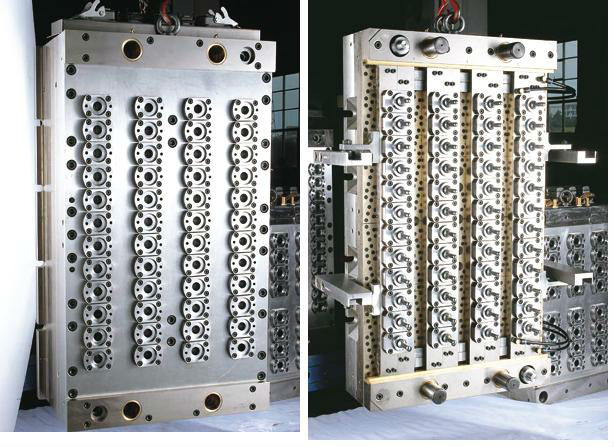

1 cavity to 72 cavities 2016 new taizhou mold Pet preform mould lastest plastic injection preform

Basic Info

Model No.: Hot runner pet preform mould

Product Description

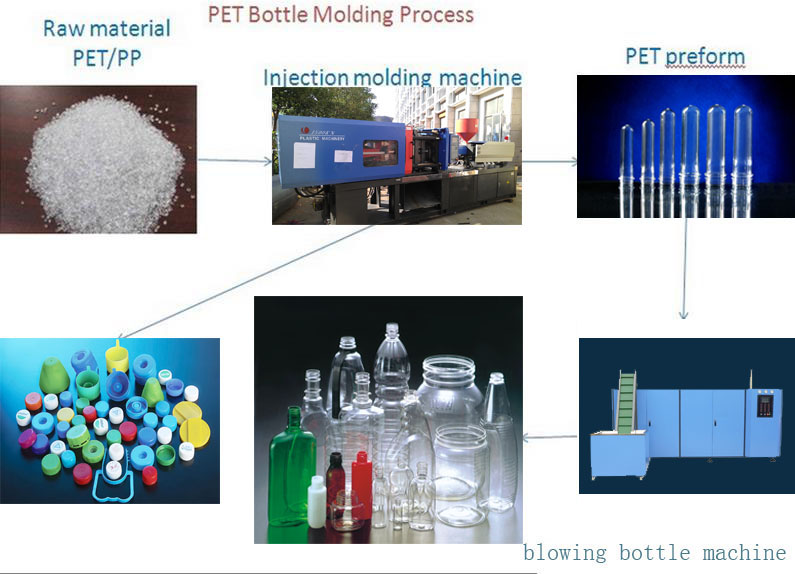

Fast cycling due to specially designed cooling circuits Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time Standard interchangeable mold components,replacement parts available within 24 hours Reliability Rugged design for long life Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers Roller cams actuate both the opening and closing actions on the thread splits Part quality Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

Fast cycling due to specially designed cooling circuits Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time Standard interchangeable mold components,replacement parts available within 24 hours Reliability Rugged design for long life Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers Roller cams actuate both the opening and closing actions on the thread splits Part quality Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms PET Preform Mould Main Components Specification and Advantages | |||||||||||||||||||||||||||||||||||||||

Main component | Specification and Advantages | ||||||||||||||||||||||||||||||||||||||

Core | 2316 steel from Sweden | high-quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance | |||||||||||||||||||||||||||||||||||||

Neck | S136 steel from Sweden, HRC >60, International standard screw neck | ||||||||||||||||||||||||||||||||||||||

Cavity | 2316 steel from Sweden Each cavity have an independent temperature controller Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm | ||||||||||||||||||||||||||||||||||||||

Body | P20 Steel material from Germany | ||||||||||||||||||||||||||||||||||||||

Hot runner plate |

2344 Steel material from Germany

| ||||||||||||||||||||||||||||||||||||||

Slider Plate | wear-resistant copper | ||||||||||||||||||||||||||||||||||||||

specially designed cooling circuits | Proper design reduce molding cycle time to 15 seconds( with proper water chiller and Injection Machine) about 3-5 shots per minute | ||||||||||||||||||||||||||||||||||||||

Hot runner design | make sure the high quality of preform products. | ||||||||||||||||||||||||||||||||||||||

Heater | Anole Germany | ||||||||||||||||||||||||||||||||||||||

valve gated design with Automatic drop | each cavity has its independent heating zone and temperature is measured by independent thermocouple. .(advantages: easily avoid some problems such as white or draw bench on bottom). Valve gated type without tail reduces labor force. | ||||||||||||||||||||||||||||||||||||||

Precessed by high presion CNC machine and numerical control loathe machine | Lowest weight and dimensional variation thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well Fast cycling due to specially designed cooling circuits Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time Standard interchangeable mold components,replacement parts available within 24 hours Reliability Rugged design for long life Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers Roller cams actuate both the opening and closing actions on the thread splits Part quality Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

Contact us if you need more details on hot runner pet preform mould ( 1 cavity to 20 cavities ). We are ready to answer your questions on packaging, logistics, certification or any other aspects about pet preform mould、mould. If these products fail to match your need, please contact us and we would like to provide relevant information. Contact us if you need more details on hot runner pet preform mould ( 1 cavity to 20 cavities ). We are ready to answer your questions on packaging, logistics, certification or any other aspects about pet preform mould、mould. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Preform Mold Premium Related Products Other Products

Hot Products 200t hand injection moulding machine/bottle injection molding machineinjection plastic mould,plastic mould,preform mould28mmplastic injection mold /plastic preform moldAutomatic filling machine 5 gallon bottle PETReverse osmosis systembottle design48 cavity bottle cap mouldTwo cavity semi automatic blowing machineFully-automatic blow moulding machine(6 cavity)Factory surpplying438tons pvc pipe fitting injection moulding machineplastic injection moulding machine priceinjection molding machine price HDX2000 IIPET BOTTLE PREFORM INJECTION MOLDING MACHINE HDX208PET FOR SMALL VOLUMEready made high quality pet preform mouldHDJS128 high quality hot sale disposable syringe making machineshaver injection molding machine | ||||||||||||||||||||||||||||||||||||||