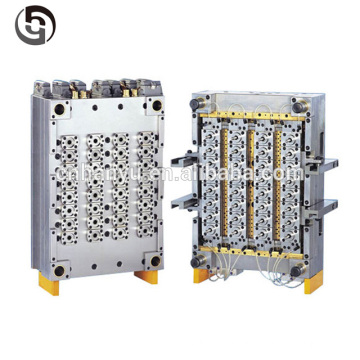

plastic injection pet preform mould

Basic Info

Model No.: 24cavity

Product Description

Product Description plastic injection pet preform mould Productivity

Fast cycling due to specially designed cooling circuits

Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time

Standard interchangeable mold components,replacement parts available within 24 hours

Reliability

Rugged design for long life

Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

Roller cams actuate both the opening and closing actions on the thread splits

Part quality

Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

The thickness and weight of Moulds are in accordance with the tubes,these measurments will change in case the products are improved.

Detailed Images

Detailed Images

Packing & Delivery

Packing & Delivery

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

* Training how to instal the machine, training how to use the machine.

Related Products

Related Products

360t plastic injection molding machine price 95.7% Response Rate Semi-automatic blow moulding machine price 95.7% Response Rate Fully-Automatic Blow Molding Machine(4 cavity) price 95.7% Response Rate

360t plastic injection molding machine price 95.7% Response Rate Semi-automatic blow moulding machine price 95.7% Response Rate Fully-Automatic Blow Molding Machine(4 cavity) price 95.7% Response Rate  Back to >>>https://cnhanyu.en.alibaba.com/

Back to >>>https://cnhanyu.en.alibaba.com/

Contact us if you need more details on plastic injection mould making. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 5 gallon pet preform mould、preform mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Fast cycling due to specially designed cooling circuits

Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time

Standard interchangeable mold components,replacement parts available within 24 hours

Reliability

Rugged design for long life

Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

Roller cams actuate both the opening and closing actions on the thread splits

Part quality

Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

Detailed Images

Detailed Images

Packing & Delivery

Packing & Delivery

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine.

Related Products

Related Products

360t plastic injection molding machine price 95.7% Response Rate Semi-automatic blow moulding machine price 95.7% Response Rate Fully-Automatic Blow Molding Machine(4 cavity) price 95.7% Response Rate

360t plastic injection molding machine price 95.7% Response Rate Semi-automatic blow moulding machine price 95.7% Response Rate Fully-Automatic Blow Molding Machine(4 cavity) price 95.7% Response Rate  Back to >>>https://cnhanyu.en.alibaba.com/

Back to >>>https://cnhanyu.en.alibaba.com/Contact us if you need more details on plastic injection mould making. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 5 gallon pet preform mould、preform mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Preform Mold

Premium Related Products

Other Products

Hot Products

200t hand injection moulding machine/bottle injection molding machineinjection plastic mould,plastic mould,preform mould28mmplastic injection mold /plastic preform moldAutomatic filling machine 5 gallon bottle PETReverse osmosis systembottle design48 cavity bottle cap mouldTwo cavity semi automatic blowing machineFully-automatic blow moulding machine(6 cavity)Factory surpplying438tons pvc pipe fitting injection moulding machineplastic injection moulding machine priceinjection molding machine price HDX2000 IIPET BOTTLE PREFORM INJECTION MOLDING MACHINE HDX208PET FOR SMALL VOLUMEready made high quality pet preform mouldHDJS128 high quality hot sale disposable syringe making machineshaver injection molding machine