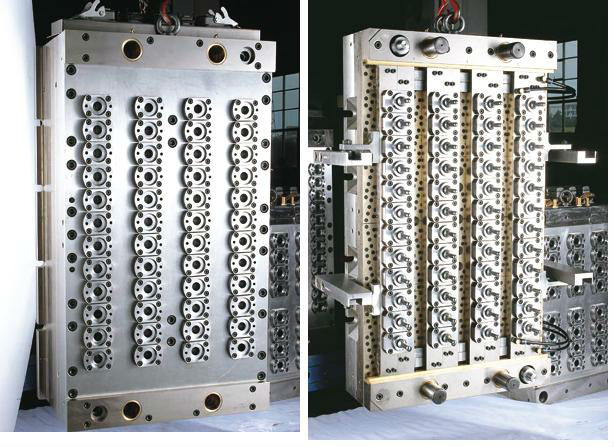

bottle preform mould

Basic Info

Model No.: 2-72cavity

Product Description

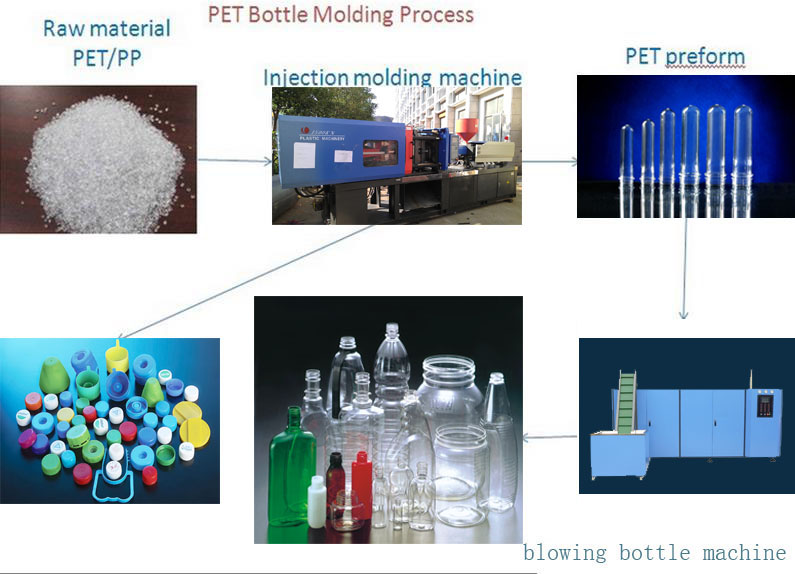

1-72 cavity hot runner preform mould

Productivity

Fast cycling due to specially designed cooling circuits

Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time

Standard interchangeable mold components,replacement parts available within 24 hours

Reliability

Rugged design for long life

Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

Roller cams actuate both the opening and closing actions on the thread splits

Part quality

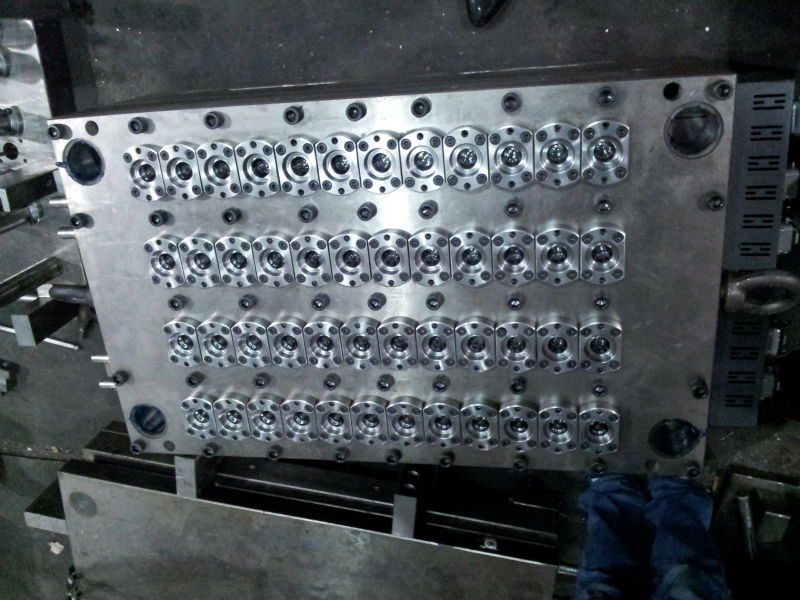

Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

| PET Preform Mould Main Components Specification and Advantages | ||

| Main component | Specification and Advantages | |

| Core | 2316 steel from Sweden | high-quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance |

| Neck | S136 steel from Sweden, HRC >60, International standard screw neck | |

| Cavity | 2316 steel from Sweden Each cavity have an independent temperature controller Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm | |

| Body | P20 Steel material from Germany | |

| Hot runner plate | 2344 Steel material from Germany | |

| Slider Plate | wear-resistant copper | |

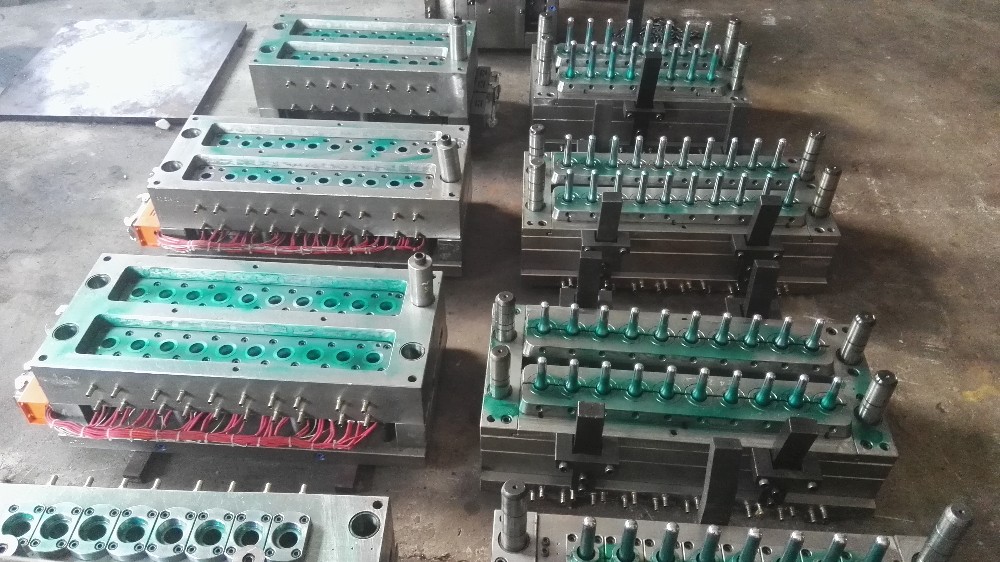

| specially designed cooling circuits | Proper design reduce molding cycle time to 15 seconds( with proper water chiller and Injection Machine) about 3-5 shots per minute | |

| Hot runner design | make sure the high quality of preform products. | |

| Heater | Anole Germany | |

| valve gated design with Automatic drop | each cavity has its independent heating zone and temperature is measured by independent thermocouple. .(advantages: easily avoid some problems such as white or draw bench on bottom). Valve gated type without tail reduces labor force. | |

| Precessed by high presion CNC machine and numerical control loathe machine | Lowest weight and dimensional variation thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well | |

FAQ2

Q:What is the delivery time?

A:15-30days for this machine.

Q:What is the payment team?

A:T/T.L/C

Q:Can i trust you?

A:YES.We are "Alibaba" verified supplier

Q:May i visit your factory?

A:Of course,welcome any time,we can also pick you up at airport or station,

and we will display our machine for you.

Contact us if you need more details on plastic injection preform mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 5 gallon pet preform mould、Pet Preform Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Preform Mold

Premium Related Products