360ton thermoplasticity thermosetting servo motor plastic injection molding machine for making plastic

Basic Info

Model No.: HY-3600

Product Description

Product Description

| | HY-36 00 Injection Machine | | ||

| Injection Unit | Model | A | B | c |

| Screw Diameter | 65mm | 70mm | 75mm | |

| Screw L/D Ratio | 1:20.6L/D | 1:17.7L/D | 1:16.5l/d | |

| Injection Volume | 1138cm³ | 1240cm³ | 1430cm3 | |

| Shot Weight | 1024g | 1120g | 1285g | |

| Plasticizing Capacity | 310 g/s | 365g/s | 395g/s | |

| Injection Pressure | 40g/s | 46 g/s | 55g/s | |

| Screw Speed | 181 MPA | 157MPA | 137mpa | |

| Clamping Unit | Clamping Force | 3600KN | ||

| Opening Stroke | 605MM | |||

| Space Between Tie-bars | 640*640MM | |||

| Max. Mould Height | 700MM | |||

| Min. Mould Height | 250MM | |||

| Ejector Stroke | 125MM | |||

| Hydraulic Ejection | 70KN | |||

| General | Pump Pressure | 16MPA | ||

| Motor Power | 37KW | |||

| Heater | 16KW | |||

| Machine Dimension(L*W*H) | 6.7*1.7*2.4M | |||

| Machine Weight | 11.5T | |||

Related Products

Preform Mold

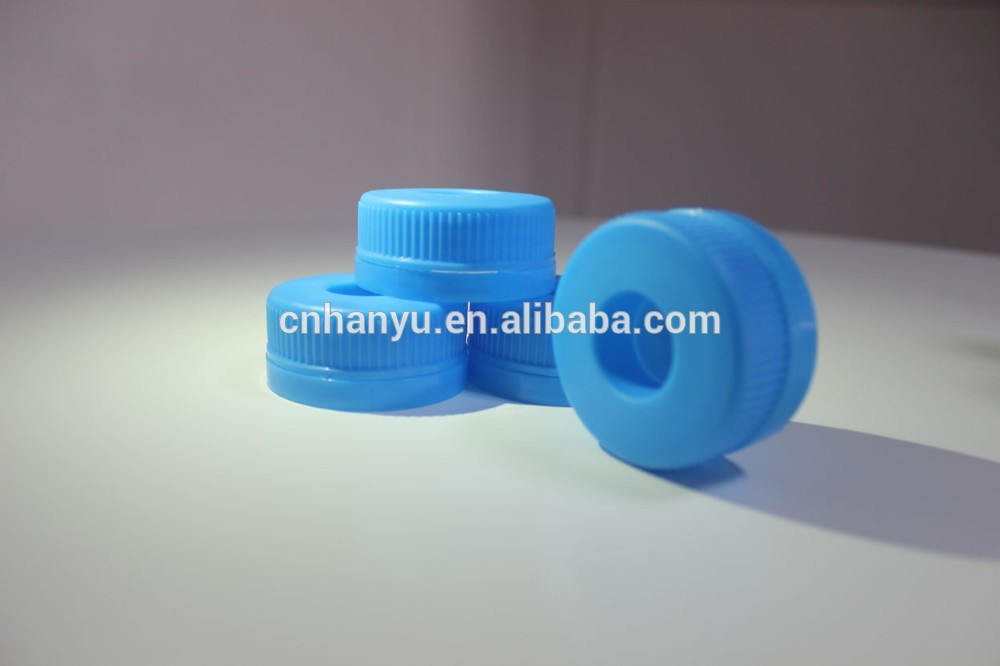

Cap Mold

Detailed Images

All of our machines are equipped with advanced electrical and hydraulic control elements imported from the USA, Italy, German, equipment:

1) Double cylinder balancing injections

2) High-torque oil-motor preplasticizing

3) Five pivots minus relief angle, double toggles, machine hingemold locking

4) Cabinet-type holder integrates the mold plate

5) Oil motor driven gear mold adjusting

6) Storage-type grease lubricating

7) Pressure and flow whole-proportion running

8) High-performance, low-noise oil pump

9) Multi-step pressure and speed adjusting

10) High-precision position linear transducer

11) Digital memory for mold group

Injection unit:

1) Four injection pressures and speeds with three additional pressures and speeds

2) Suck back function

3) Cold start protection

4) Pre-suck back function

5) Linear displacement transducer accurately monitor injection

position, providing optimum. injection accuracy andcontrol

6) Temperature control

7) Heating Status indication

Clamping unit:

1) Three clamp close and open pressures and speeds

2) Mold protection function

3) Hydraulic ejector stroke controlled by transducer

4) Automatic hydraulic die-height adjustment driven by planetary

gears system

5) Adjustable support under moving platen

6) Automatic high pressure toggle lubrication with low oil level alarm

7) Mechanical, electrical and hydraulic safety interlock device

8) Linear displacement transducer controls clamping position

Other parts:

1) Independent core in / out pressure and speed

2) Hydraulic unscrewing sequence

3) Hydraulic oil high temperature alarm

4) System pressure gauge

5) Shot counter and reset function

6) Malfunction alarm light

7) Self-diagnostic function

8) Emergency stop buttons placed both front and rear of the machine to provide easy access

Our Factory

Packing & Delivery

| Packaging | |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Contact us if you need more details on Automatic Injection Moulding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Machine、Injection Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Injection Machine

Premium Related Products

Other Products

Hot Products

200t hand injection moulding machine/bottle injection molding machineinjection plastic mould,plastic mould,preform mould28mmplastic injection mold /plastic preform moldAutomatic filling machine 5 gallon bottle PETReverse osmosis systembottle design48 cavity bottle cap mouldTwo cavity semi automatic blowing machineFully-automatic blow moulding machine(6 cavity)Factory surpplying438tons pvc pipe fitting injection moulding machineplastic injection moulding machine priceinjection molding machine price HDX2000 IIPET BOTTLE PREFORM INJECTION MOLDING MACHINE HDX208PET FOR SMALL VOLUMEready made high quality pet preform mouldHDJS128 high quality hot sale disposable syringe making machineshaver injection molding machine