cap making machine

Basic Info

Model No.: HDJS288

Product Description

Product Description

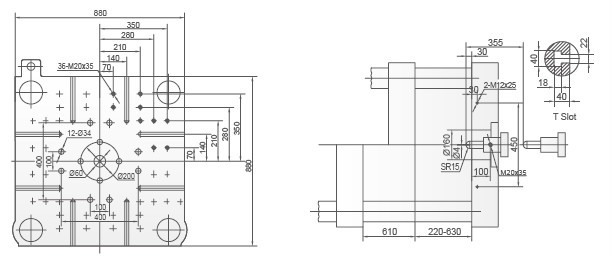

| ITEM | UNIT | DATA | |||

| Injection | Screw Diameter | mm | 60 | 65 | 67 |

| Screw L/D Ratio | L/D | 21.7 | 20 | 19.4 | |

| Injection Volume | cm3 | 686 | 805 | 856 | |

| Shot Weight | g | 624 | 733 | 779 | |

| Injection Pressure | Mpa | 190 | 162 | 152 | |

| Clamping | Clamping Force | KN | 2880 | ||

| Opening Stroke | mm | 610 | |||

| Mould Thickness(Min-Max) | mm | 220-630 | |||

| Space Between Tie-Bars | mm | 610×610 | |||

| Ejector Force | KN | 70 | |||

| Ejector Stroke | mm | 165 | |||

| General | Motor Power | KW | 26 | ||

| Heater | KW | 18 | |||

| Pump Pressure | Mpa | 16 | |||

| Machine Dimension | m | 6.5×1.6×2.2 | |||

| Machine Weight | T | 8.5 | |||

| Mould Orientation Ring Diameter | mm | Φ160 | |||

| Nozzle Radius | mm | SR15 | |||

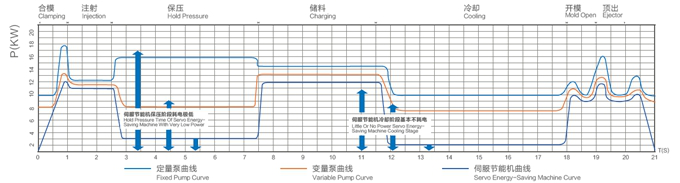

HDJS Servo Energy-Saving Machine

Superior Energy Efficiency

To Save Power Consumption

Cooling phase, the motor does not need to work, power consumption is 0.

Compared with the traditional Injection molding machine can save electricity <80%

Saving Water And Fuel

Compared with the traditional hydraulic power system of the hydraulic oil

consumption reduce

1/4 ~ 1/3, can achieve without cooling, thus greatly saving water.

Living longer 2~3 Double.

Power Consumption Curve Comparison Chart

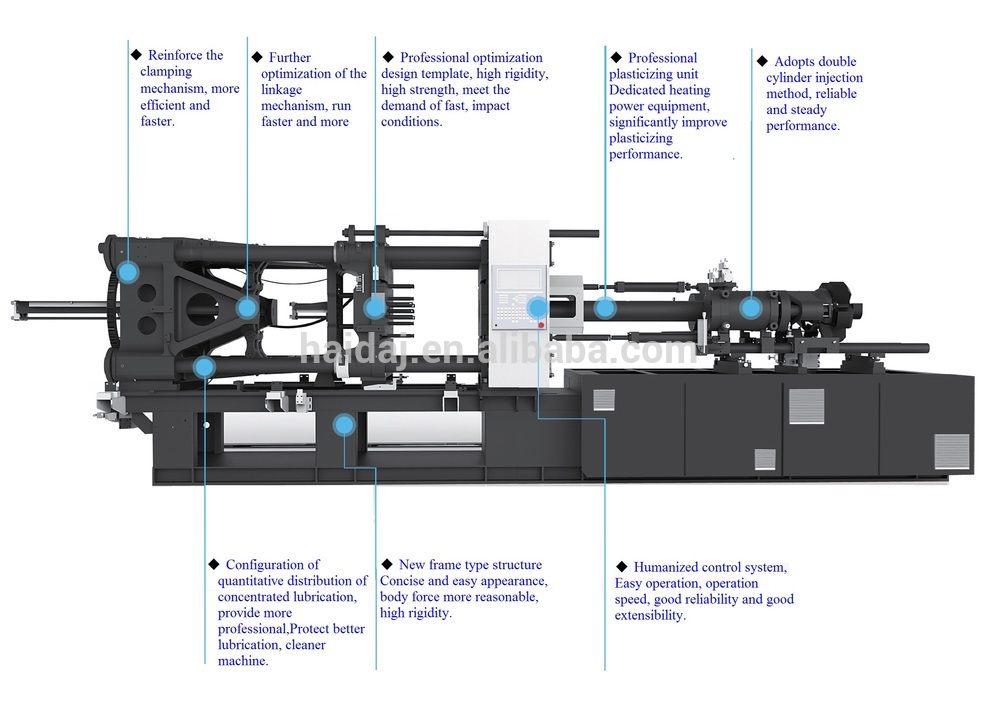

Improve The Production Efficiency

Quick Response And High Efficiency

injection molding machine to achieve maximum output in 0.05 s

50 rpm can be up to 140 bar

High Repeat Precision, Save Raw Materials

Repeated injection precision can reach <=3%

Pressure Is Stable, Improve the Quality Of Molding

Pressure fluctuation quantity is less than + / - 0.5 bar

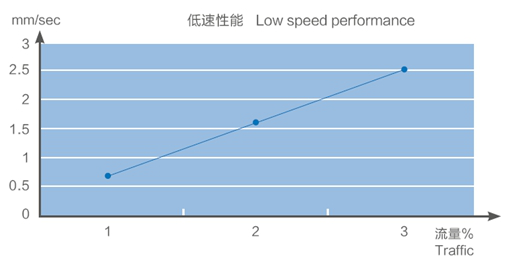

Stable At Low Speed

Closedloop control pressure and flow, at low pressure and low flow operation performance is

particularly outstanding, shoot rubber speed in less than 1 mm/SEC without crawling, pulse, highstability. System according to the actual product process requirements, set arbitrary pressure

and flow, avoid excess heat generation, the oil temperature relative to the traditional injection

molding machine is stable. In addition, the pressure flow automatic compensation when motion, maintain the stability of the pressure and flow rate, high control accuracy and repeat precision.

Machine Service Life Longer And Cleaner Working Environment

Less Noise Emissions

Low Heat And Cooling Energy Demand Is Low,

More Suitable For Production Environment With Air Conditioning

Injection Molding Machine boot into the steady-state oil temperature rise of 8°C to 10°C

Machine in Details

Meticulous division of labour, consecutive processes, professional experience of manufacture and high standard equipment ensure the high quality of the machine. We put stress on every working procedure to meet the requirements of customers for high quality. Recently, we have introduced high precision machining tools,with the equipment of cutting machine tools, heat-treating facilities, check out test sets and painting facilities, the processing ability of Haida Company, especially for the large and supersized machine reach a high level in plastic machine industry while the quality of the machine is ensured at the same time.

Good products must be based on good equipment and technique. Haida company take advantage of new equipment and technique in the world to develop the design of machines. We don't hesitate to input more about these. Equipped-well design center, Vanward institute in plastic machine industry, R&D Center, CAD design Center and test Center ensure the vanward design of Haida company.

Packaging & Shipping

Our Services

There are more than 10 Agents of our Haida located in the world.

Engineers available to service machinery overseas

Company Information

NINGBO HAIDA Plastic Machinery Co., Ltd. is a large professional production base specialized in manufacturing HDX HDJS HDJL series automatic plastic injection machines and enjoy high reputation in the plastic machinery industry association, vice President of units. In recent years, our company undertake entity of project under the new high-tech enterprise, state inspectionfree product, China famous brand, Zhejiang province

famous brand and Zhejiang province well known product. In 2000, we had the right of selfimport and export

and had registed our brand in more than ten countries and areas. Our company was accredited by BCC (ISO9001) and CE certificate in 2001 and ISO14001 and OHSAS18001 in 2007.

Established in 1992, Ningbo Haida Plastic Machinery Co., Ltd. become one of the most famous companies in the plastic machinery industry. It covers an area of more than 100 thousand square meters and has a total asset of RMB 350 million. There are 420 workers and staff members including 30% professionals with middle or senior class techinical certificate. Famous senior engineers and experts are invited regularly as our advisers. Our HDJL and HDJS series variable pump and servo motor machines are well-known by our clients.

FAQ

2005 year State Inspection-Free Product

2005 year Zhejiang Province Well-Known Product

2005 year Zhejiang Province Well-Known Trade Name

2005 year National Torch Program. High-tech Enterprise

2001year CE Certification issued by Germany TüV Company

2001 year BCC(ISO9001) (2000 Version)

Contact us if you need more details on Cap Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cap Making Machine、Cap Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : HDJS Energy Saving Machine