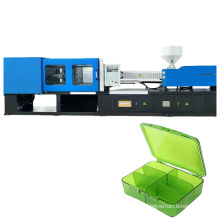

GS238 Plastic Water Bottle Lid Cover Closure Cap Making Injection Moulding Machine

Product Description

GS-D

GS-D Plastic Injection Machine of oil-electric compound system control series is the product newly developed by Guangsu Company with features of economic benefits, energy saving, high response and low noise.

Structure principle: during actual working status, the system directly feedbacks the pressure-flow rate signal through exit pressure sensor of oil pump and cycloscope to the high speed servo driver. The servo driver gives out electric signal to servo driving motor and oil pump, allowing for corresponding change of pressure and flow rate, therefore, the closed circuit control of pressure and flow rate is realized.

Structure principle: during actual working status, the system directly feedbacks the pressure-flow rate signal through exit pressure sensor of oil pump and cycloscope to the high speed servo driver. The servo driver gives out electric signal to servo driving motor and oil pump, allowing for corresponding change of pressure and flow rate, therefore, the closed circuit control of pressure and flow rate is realized.

Advantages:

1. Energy-saving: Super low energy consumption, saving energy about 30% as compared to load sensitive variable pump, and about up to 80% as compared to constant flow pump, and its energy saving effect is comparable to the fully electric forming machine. 2. Low noise Reduce greatly the noise produced by pressure control operation. 3. Reducing cost for long term

Realize energy saving and reduce running cost. Compared to electric type, the initial investment and maintenance cost is reduced greatly. 4. Easy operation Parameters setting and system speed adjustment are very simple digital operations. The customer only needs to operate the control panel just like common machine. 5. High performance High response (30ms-130ms), high stability, accurate repeatability and energy saving.

Machine Model | GS238 | |||||

Injection Unit | A | B | C | |||

Screw Diameter(mm) | 45 | 50 | 55 | |||

Length/Diameter Ratio(L/D) | 22 | 20 | 18.5 | |||

Theoretical Shot Size(cm³) | 342 | 456 | 551 | |||

Shot Weight(PS)(g) | 311 | 415 | 502 | |||

Injection Pressure(MPa) | 207 | 177 | 143 | |||

Maximum Screw Speed(rpm) | 171 | |||||

Clamping Unit | ||||||

Clamp Force(KN) | 2380 | |||||

Opening Stroke(mm) | 475 | |||||

Distance Between Tie-bars(mm) | 520*520 | |||||

Max. Mold Height(mm) | 540 | |||||

Min. Mold Height(mm) | 200 | |||||

Ejector Stroke(mm) | 140 | |||||

Ejector Force(KN) | 62 | |||||

Drive Power(kW) | 18.5 | |||||

Servo Drive Power(kW) | 24 | |||||

Heating Capacity(kW) | 11.5 | |||||

Machine Dimensions(m) | 5.45*1.5*2.3 | |||||

Machine Weight(t) | 6.9 | |||||

Main Features

1. After preform injection, the heat is used for bottle blowing, no need of preform packaging, storage, reh- eating and other

working procedures.

2. Less land occupation, simple management, high degree of automation, less labor intensify (1 person can control more than 3 machines).

3. With a temperature adjustable station, suitable for complicated shape, difficult forming products (such as PP IV solution bottles).

4.The compact structure greatly shortens the production cycle and enhances productivity.

5.Adopt variable pump and servo motor, maximally reduce energy consumption.

6.The replacement of the mold cost is far lower than similar foreign equipment.

working procedures.

2. Less land occupation, simple management, high degree of automation, less labor intensify (1 person can control more than 3 machines).

3. With a temperature adjustable station, suitable for complicated shape, difficult forming products (such as PP IV solution bottles).

4.The compact structure greatly shortens the production cycle and enhances productivity.

5.Adopt variable pump and servo motor, maximally reduce energy consumption.

6.The replacement of the mold cost is far lower than similar foreign equipment.

Product Categories : (GSD)Servo Motor Injection Moulding Machines

Other Products

Hot Products

200t hand injection moulding machine/bottle injection molding machineinjection plastic mould,plastic mould,preform mould28mmplastic injection mold /plastic preform moldAutomatic filling machine 5 gallon bottle PETReverse osmosis systembottle design48 cavity bottle cap mouldTwo cavity semi automatic blowing machineFully-automatic blow moulding machine(6 cavity)Factory surpplying438tons pvc pipe fitting injection moulding machineplastic injection moulding machine priceinjection molding machine price HDX2000 IIPET BOTTLE PREFORM INJECTION MOLDING MACHINE HDX208PET FOR SMALL VOLUMEready made high quality pet preform mouldHDJS128 high quality hot sale disposable syringe making machineshaver injection molding machine